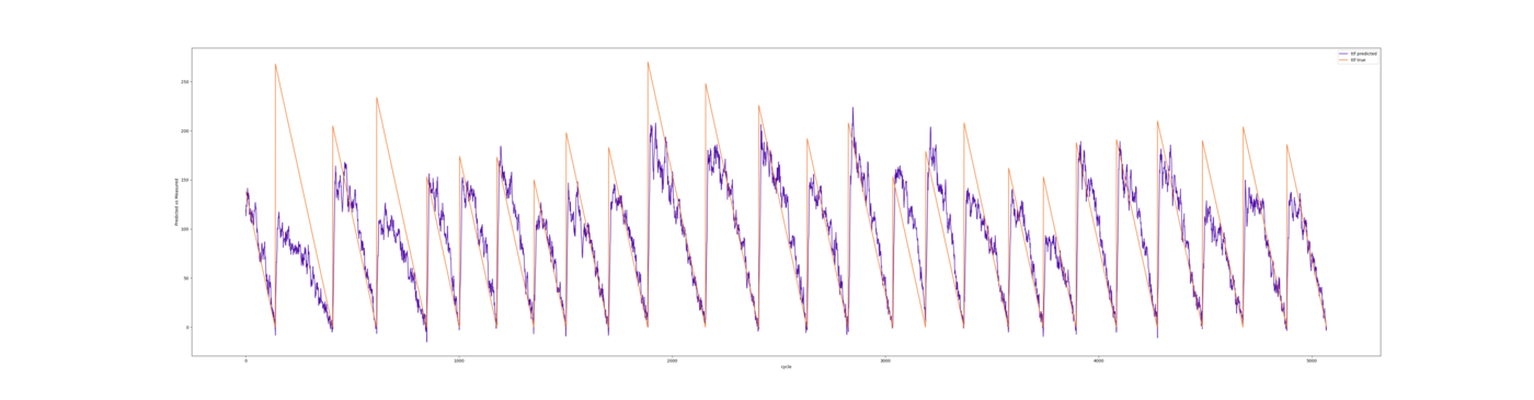

In a previous blog post we showed how Machine Learning can estimate the Remaining Useful Life of a …

Predictive Maintenance with Cameras

Often when we talk about predictive maintenance, we refer to the method by which we predict the …

Retrofitting of Predictive Maintenance

Should Predictive Maintenance be a standard add-on when you buy new machines or can it be added to …

Estimating the Remaining Useful Life on an Aircraft Engine

In this blog post, we will see how much better a machine learning model we can create by having more …

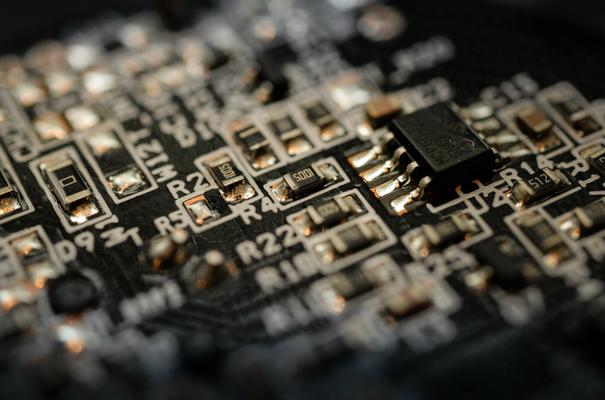

What to look for in Vibration Sensors for Predictive Maintenance

Selecting the right sensors for predictive maintenance can be a jungle. This blog post will give you …

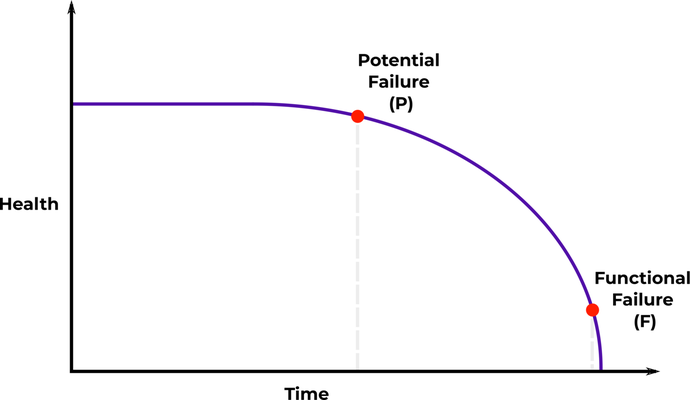

The P-F Interval and Predictive Maintenance

What is the P-F interval and why is it important when talking about predictive maintenance? In this …

We have talked about it for years now. Consultancies have been saying for a long time that we need …