In this blog post we will go through the different approaches to predictive maintenance. Right data is always the foundation and different types of machine learning algorithms can be used depending on the current situation and the problem/value we are aiming for.

Predictive maintenance is all about predicting when equipment or component will fail/breakdown before they happen.

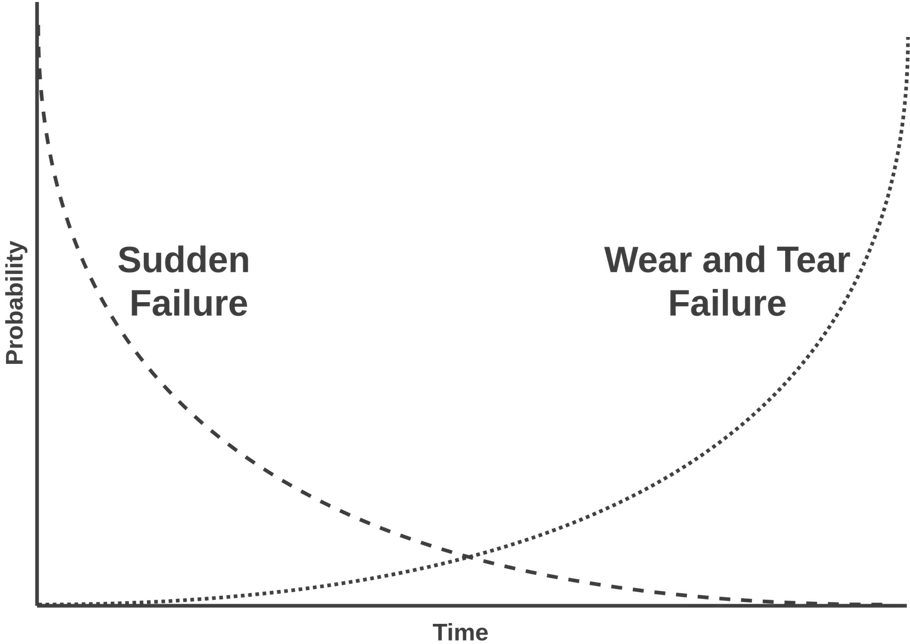

There are two main scenarios when we look at breakdowns.

Sudden breakdowns that happens unexpectedly and without any warning.

Wear and tear breakdowns happend over time due to wear.

Today these types of scenarios are handled in the following way.

Sudden Breakdowns

They tend to happen without any notice and companies try to repair as fast as possible but it often end up being reactive. Spare parts are stored locally according to the previous breakdowns history so they can be available as fast as possible. Many companies will have service agreements with service providers or have an internal technical team that can fix the problem. Service intervals are planned to reduce the possibility that the breakdown will happen, but still with a focus to have reasonable maintenance cost.

Wear and Tear Breakdowns

Many companies maintain their equipment according to fixed service intervals, e.g. operated hours, with information from component or machine suppliers. The service intervals is designed to make sure that the number of breakdowns for critical components are reduced as much as possible, and they are defined based on historical data and experience. The general approach is that it is better to have a reliable production and high uptime, and accept higher maintenance cost. If you do this you are running by the “lowest denominator”.

The probability of the different types of breakdowns occuring over the life time.

Predictive Maintenance

When we approach predictive maintenance we always start with identifying the end goal where we look for value creation. The next logical step is to look into the current available data that can tell us something about the problem.

Here it is important to focus on the right data and not only on the overall amount of Big Data available.

Depending on the amount and quality of data there are several different machine learning algorithms that can be used, they all have different advantages and disadvantages and they are heavily dependent on the data quality.

Predictive Maintenance (Sudden Breakdowns)

To solve this issue with predictive maintenance there are several ways forward depending on the data available. With a limited amount of data and no recorded breakdowns it is possible detect data which deviates from normal situations. In this case we use unsupervised learning.

With more data available and earlier detected breakdowns it is possible to give a more precise prediction and also a better warnings. In this case we can use supervised learning and label the data set with input from earlier breakdowns. If your maintenance team have a maintenance system and keep it updated this information can likely be found here.

The model looking for sudden breakdowns will give a warning in minutes or hours before a breakdown occurs.

Predictive Maintenance (Wear and Tear Breakdowns)

To solve this issue we need data covering the entire life cycles of the component also including breakdown related to a wear and tear situation. Our experience is that a data set with as few as 7 breakdowns can give a quite robust model. We will in this case use a supervised machine learning algorithm.

The model will give a warning in days or weeks before a breakdown making it possible to order parts and plan the maintenance.

Conclusion

Predictive maintenance is about looking into the future to predict breakdowns on key components in your production. It is possible to give a predict and give a warning for both sudden and wear and tear breakdowns. There is a great potential in this area, in many years equipment have either been overmaintained or underserviced in the absence of better tools to solve this challenge. Now there are better tools available like predictive maintenance, You just have to start with the aim of increasing uptime on production equipment and reduce maintenance costs at the same time.

// Lars Endrup, Business Development Manager @ neurospace