What is the P-F interval and why is it important when talking about predictive maintenance? In this blog post you will get an introduction to the P-F interval and how predictive maintenance with machine learning can improve the detection of potential failure and give you the possibility to plan maintenance before a failure happens.

P-F interval

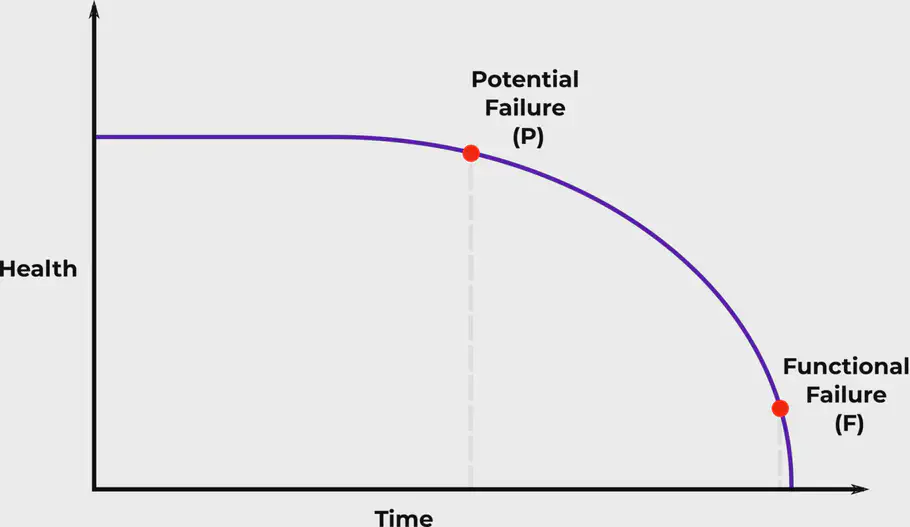

The P-F interval describes the time cycle between the initial detection of a potential failure (P) and the actual functional failure (F). Most failures does not take the same time to occur after the symptom is detected e.g. even if you remove all grease from a bearing (P) it will take time before it causes a functional failure (F). When doing predictive maintenance we want to detect the potential failure and its symptoms as early as possible to be able to monitor the degradation of the component.

P-F Interval showing the cycle between potential failure until functional failure

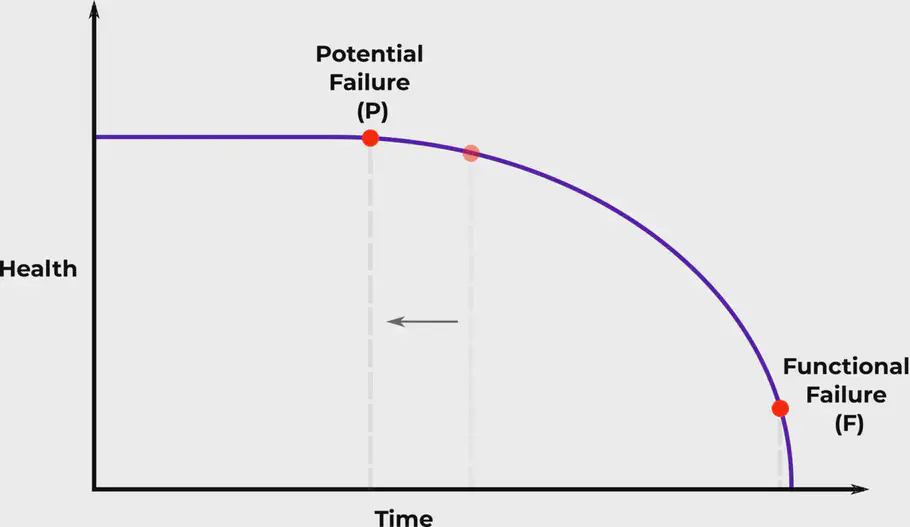

But what if it is possible to increase the p-f interval, by moving the (P) to the left, or put in another way: What if we could detect the failure earlier? Is it possible to continuously monitor for potential failures with sensors? The answer to both questions is: Yes. It is possible to monitor continuously to spot potential failure (P) earlier with sensors and Predictive Maintenance. This will likely help you and your maintenance department plan better for when assets can be taken out of production for maintenance, lessen manual inspections and prevent breakdowns. This has the potential of not only reducing costs but also improve uptime of the asset. In neurospace we sometimes refer to this as shifting the P to the left as seen in the diagram.

P-F Interval where we are shifting the P to the left

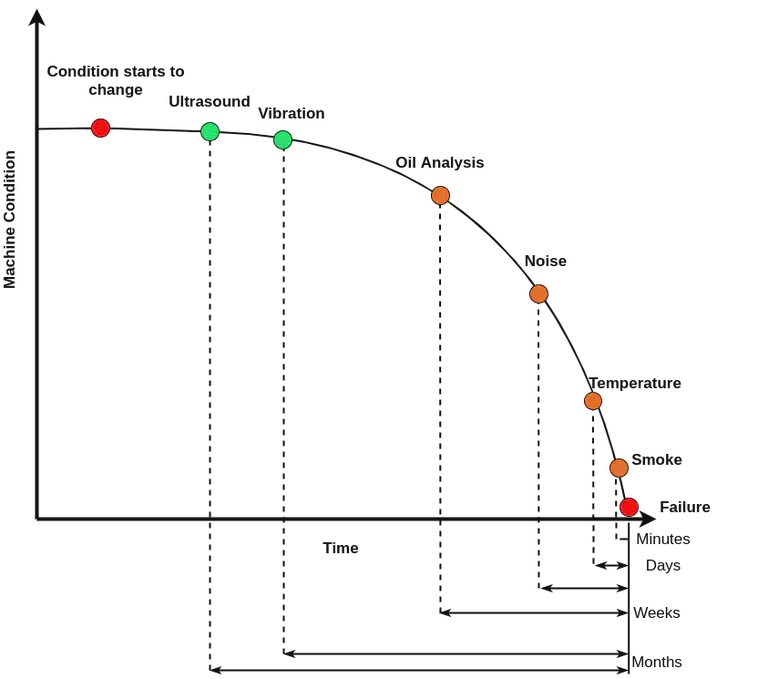

The important thing here is to understand how the P can be shifted to the left. This is easiest defined by looking at sensors and what human can observe in the real world. For example it is easy for humans to detect smoke or even heat from components on assets but detecting if minuscule vibrations are present is hard for us. However, sensors specialized for vibration and ultrasound can detect these small changes in vibrations that often are early signs of a conditional change in the component’s health (potential failure (P)). In this way we can use the P-F interval to describe which sensors allows us to detect the potential failure the earliest or shift the P to the left.

P-F Interval and how large it is depending on which sensors you have available

As you can see in the diagram it is possible to shift the P to the left and detect potential failures earlier by using vibration or ultrasound sensors. By using vibration sensors you can detect potential failures months in advance and get big improvements if you are relying on smoke or temperature changes today.

It is important to mention, that even though you move the P to the left, thus gets a larger interval between P and F, it does not imply that you should perform maintenance at the moment you spot a change in the component’s condition. If you use vibration sensors to improve your P-F interval, you might have 6 or 9 months before a potential failure causes a breakdown. This is why you need to monitor the component’s health throughout the degradation, to find the optimum point to perform maintenance, and this can be done by the help of Remaining Useful Life predictions.

We recommend that you read what to look for in vibration sensors for predictive maintenance if you are interested in know more about which criteria is important when selecting a vibration sensor.

// Rasmus Steiniche, CEO @ neurospace