In a previous blog post we showed how Machine Learning can estimate the Remaining Useful Life of a turbofan engine.

In this blog post, we will put our internal library, Cohen to the test, by estimating the Remaining Useful Life on NASA’s Turbofan engine with six different conditions (0 to 20,000 feet), and one fault mode, HPC Degradation.

Afterwards, we will test it when having two fault modes: HPC Degradation and Fan Degradation.

Who is Cohen?

neurospace’s internal library is not named Cohen by coincidence.

When developing our internal library for predictive maintenance, we wanted to honor a woman named Judith Love Cohen, a female aerospace engineer in NASA.

In a time where few women became engineers, Judith Love Cohen was a pioneer, and did what only few people did.

Her work at NASA on the Apollo programme is according to her family the highlight of her career, and for good reasons.

Judith Love Cohen was one of the people working on the Abort-Guidance Sytstem in the Lunar Excursion Module, which was a critical component for the safe return of Apollo 13’s astronauts Lovell, Swigert, and Haise.

She is without any doubt a woman to be inspired by.

Cohen is our internal library for creating custom Machine Learning models for predictive maintenance, with automatic hyperparameter tuning, and validation.

Cohen is made, to secure that the machine learning model is designed for your data. A custom model, for your machines, in your environment, and with the workload you have on the machine.

The Machine Learning model is created by itself. Thus, we are creating custom models, faster than ever before.

In this blog post, we put Cohen to the test with a new dataset from NASA, where we now estimate the life of the jet engine when it is operating between 0 to 20,000 feet.

Estimating the Reamining Useful Life with Cohen

With Cohen, we can quickly generate the label we need, and create custom Machine Learning models.

Three lines of code, and we have all we need.

In the first test we will test our library on a dataset with six conditions (0 to 20,000 ft) and only detecting one type of breakdown - the HPC degradation.

In the second test, we will try to estimate the remaining useful life, when breakdowns are caused by two different causes: HPC degradation and Fan degradation. The aircraft engine will still be measured while operating from 0 to 20,000 ft.

Six Conditions and One type of Breakdown

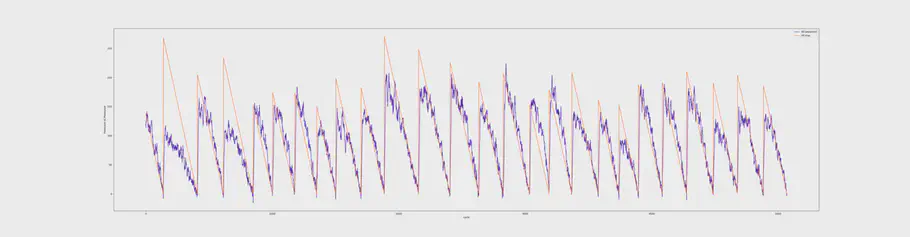

The image below shows the result when having 50 breakdowns logged in a operating journal.

The orange line in the image shows the true remaining useful life, while the purple line shows the estimated value according to the model.

Breakdown occurs when the orange line hits 0. And the beginning of the orange line visualizes the total life of the component.

The model with the highest accuracy or the lowest loss value, is not necessary the best model for your problem.

We can get a lower loss than visualized on the table below, however, the performance of the model when we are close to a breakdown gets worse.

| Mean Absolute Error | Mean Squared Error | |

|---|---|---|

| Model performance | 0.1169 | 0.0275 |

When solving a problem with Machine Learning, even with statistics, it is important to never just look at accuracy or loss, as the best model in this case, according to the parameters, may never predict the breakdown correctly. The best Machine Learning model will e.g. in this case, be the one that is most accurate as we approach 0, the days leading up to the breakdown. Since we estimate time, we will ask the Machine Learning model to estimate something linear, but the truth is that wear is more exponentially downward as we have previously talked about in connection with the PF interval. Much of the data in the early stages of a component’s lifetime will therefore be similar, and estimating that it is linear is not something we expect the model to do. But we want to have a high precision when the condition of the component changes. And how early we can do this depends 100% on your data quality and data sources.

As visualized, we successfully predict the breakdowns when having six conditions, and 1 type of breakown. Let’s see what happens when we have two types of breakdowns.

Six Conditions and Two types of Breakdown

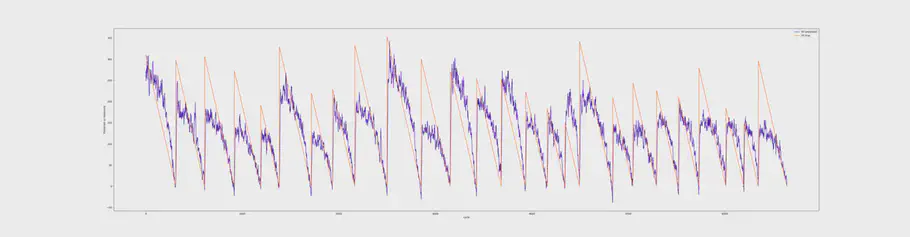

The image below shows the model generated by Cohen, when having six conditions and two types of breakdowns.

The predictions are less accurate in some of the breakdowns, but still more confident the closer we get to the breakdown. Breakdown number 17 is the least accurate prediction, but also have a very small lifecycle, of only approximately 125 cycles. However, when a model starts to estimate a vertical downgrade in the health condition of a component’s life, when the Remaining Useful Life is at 100, all alarm systems should indicate something is wrong.

Cohen is widely used in neurospace to fast create custom predictive maintenance solutions that fits to your machines.

However, if you do have a wish of estimating the Remaining Useful Life, and wish for the model to be accurate within months before the breakdown occur, you need the Right Data, from the right sources and in the right sample frequency.

For your company, this means we can create a model that estimates the Reamining Useful Life on your equipment faster, cheaper, and more efficient than ever.

// Maria Hvid, Machine Learning Engineer @ neurospace

Bibliography

In memory of Judith Love Cohen: Mother, Wife, Friend, Author, Engineer