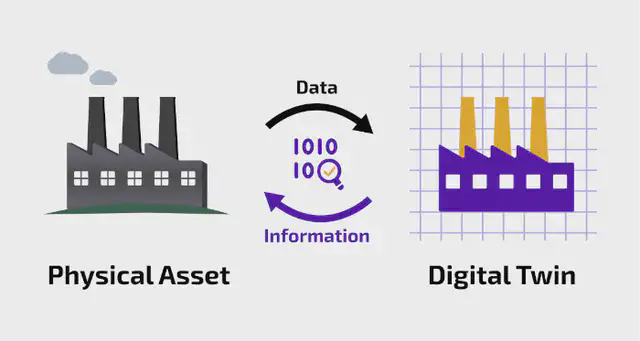

Over recent years, Berliner Energie und Wärme (BEW) has undergone a significant digital transformation, resulting in a digital twin. This twin calculates and simulates the grid’s hydraulic capabilities, thereby enhancing overall performance and efficiency. However, based on hydraulic physics, it requires substantial resources to expand as the city’s grid grows.

Facts about the company

Berliner Energie und Wärme (BEW) operates one of Europe’s largest and most complex district heating systems. It is not only separated into several grids but also varies significantly in its technical construction. It comprises over 25,000 substations across four different grids, supplying district heating to approximately 700.000 households.In collaboration with Neurospace, BEW’s progressive System Digitalisation Team identified an opportunity to expand the digital twin’s capabilities using a data-centric approach. This led to the development of two distinct use cases, enabling the digital twin to identify patterns within the grid through Artificial Intelligence (AI). These cases were seen as a unique way to enrich and expand the digital twin using the patterns generated by the data.

Way of working

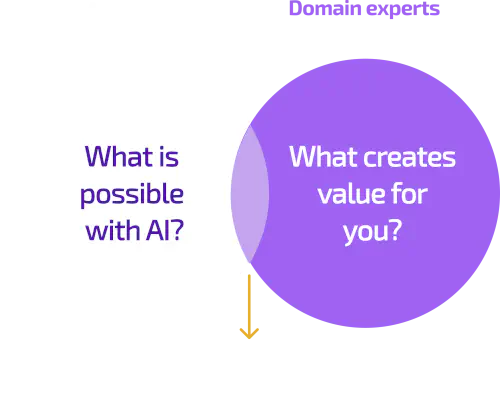

Any AI project mandatorily requires the inclusion of domain experts, as their specialized knowledge is crucial for guiding the AI development process, interpreting results accurately, and ensuring the models are relevant and effective within the specific problem domain. This collaboration ensures that the AI is not just technologically advanced but also deeply integrated with the practical realities and nuances of the field, leading to more successful and impactful outcomes.

The first initiative, named “SMART-Meter,” aimed to create an AI model for forecasting heat load on substations 12-24 hours in advance. Leveraging AI’s core capability in pattern recognition, the primary goal was to prove the feasibility of predicting heat load for a single substation. Subsequent goals included expanding this capability to predict heat load for specific substation types (e.g., kindergartens, offices, residential/business mixes) and different heat supply types (e.g., room heating only vs. room heating and water). Success was defined by achieving the first hypothesis, but if the latter two were also possible, it would significantly reduce development costs and facilitate the training of generalized AI models.

The second initiative, “Hydraulic Weak Point,” aimed to train a model that would provide data-driven feedback to operators. This model would identify situations where known weak points could lead to hydraulic limitations, causing households to lose heat during peak times. Addressing these weak points is crucial for lowering the temperature of the supply heat and, consequently, reducing Berlin’s district heating production.

Less is more, forget Big Data

For this 2-month Proof of Concept (PoC), a clear scope and data availability were paramount. It was also crucial to test the PoC in a smaller environment; thus, BEW and Neurospace agreed on the North-Eastern part of the grid for the two cases. The team identified available data and common data points across substations, noting that not all substations had the same data. More relevant data not only improved the AI model but also enabled faster training without large data centers. This approach acknowledges the evolving nature of the future, necessitating AI model retraining over time.

Throughout the project, BEW demonstrated strong capabilities in data availability and quality, which was instrumental in enabling a successful Proof of Concept in just two months.

Maria Hvid

CAIO, Neurospace

SMART-Meter model

For the initial proof of concept, two substations, both primarily serving households (over 80% customer base) and representing common network configurations, were chosen: one with a specific heating type and another with a mixed heating type. The first substation’s 12-hour forecast showed an average deviation of ±7.14kW, and its 48-hour forecast deviated by ±8.28kW. For the second substation, the 12-hour forecast had an average deviation of ±6.21 kW, and its 48-hour forecast deviated by ±6.60 kW. While the models effectively captured heat load trends for typical customer and heating types, highly fluctuating patterns presented a challenge. The results suggest the feasibility of developing “type” substation models using the same underlying code, which could substantially lower implementation and maintenance costs making a much stronger return on investment.

Hydraulic Weak Point Model

Two models were developed using operational data, smart meter readings, and weather forecasts. The first model, designed to predict pressure differences at key network points, achieved an accuracy of ±0.07 bar. The second model, which forecasted supply water movement, was accurate to within ±3.53℃. Both models performed effectively even with novel data. While adept at predicting system behavior within normal operating ranges, the interconnectedness of the heating system, where changes in one part affect others, poses a challenge for the current models to fully comprehend causal relationships. Although deemed successful, further study is recommended to better understand the individual effects of various factors.

How to make a succesful Proof og Concept using AI

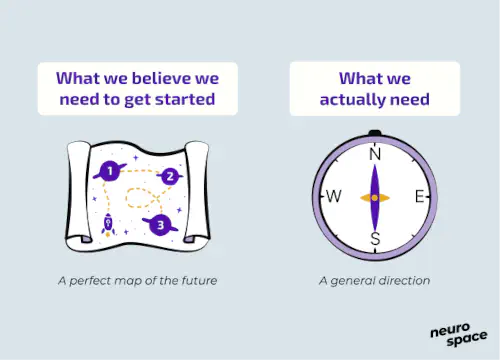

- Be specific: Clearly define the direction of what you aim to solve, what constitutes success, and how success will be measured.

- Ensure data availability: It is paramount that data is accessible before starting, as many systems may not be designed for the current AI era and can bottleneck projects.

- Keep it simple: Prioritize simplicity and make necessary compromises instead of expending resources on a “perfect” solution that is likely to change significantly before implementation.

- Embrace failure: Innovation inherently involves trial and error. Not all AI projects will succeed, but the successful ones will justify the effort.

- Innovation: AI is about working with people, having the right domain experts are crucial for success and will lower the amount of data that is needed.

Smaller implementations

With two successful cases proving that it is possible to make predictions on heat load and weak points. At this stage the AI models foundations are made, but it is still necessary to mature them for production. This made the basis for making an implementation in a selected area where there was a hydraulic weak point and a good amount of substations for a real world application. This will enable the digital twin to make predictions on the heat load and then use these data as meta data to give an indication of the hydraulic limitations in that area to the operators.

The need of direction